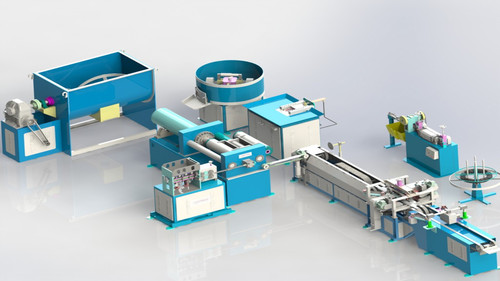

Welding Electrodes Production Line

Price 400000 INR/ Unit

Welding Electrodes Production Line Specification

- Automation Grade

- Semi-Automatic/Automatic

- Power Supply

- 380V/50Hz or as per requirement

- Weight

- Approx. 8-10 Ton

- Production Capacity

- 24-36 tons/day (depending on configuration and model)

- Features

- Energy efficient, compact design, high productivity, user-friendly operation, low maintenance

- Dimension (L*W*H)

- Approx. 25m x 2.5m x 3m

- Cooling System

- Water cooling and air cooling system

- Working Temperature

- Ambient to 50C

- Usage & Applications

- Manufacturing of various types and sizes of welding electrodes

- Material

- Heavy-duty mild steel with anti-corrosive coating

- Noise Level

- 85 dB

- Drive Type

- Electric motor-driven

- Control System

- PLC-based control system

- Size

- Standard and customizable sizes available

- Speed

- Variable, up to 120 m/min

- Machine Type

- Welding Electrodes Production Line

- Baking Oven Temperature Range

- Up to 350°C

- Coating Material

- Compatible with rutile, basic, and cellulosic types

- Painting System

- Optional, with quick-drying feature

- Wire Feeder System

- Precision feeder with speed control

- Dust Collection

- Built-in dust extraction unit

- Voltage Tolerance

- ±10%

- Safety Systems

- Overload protection, emergency stop, interlock system

- Electrode Diameter Range

- 2.5 mm - 5.0 mm

- Operator Interface

- Touch-screen HMI

- Binder Feeding Method

- Automatic

- Installation Area Required

- Minimum 70 sq.m.

- Extrusion Pressure

- 6-12 MPa

Welding Electrodes Production Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 45 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About Welding Electrodes Production Line

We are one of the most promising exporters of Welding Electrode Production Line in India. Our machinery render trouble free performance for longer period of time. We provide comprehensive range of products such as welding electrode manufacturing machinery, welding electrode equipments, welding electrode accessories and welding electrodes. Products served by us are made up of quality raw materials, which increase their durability and efficiency.

Features:

- Rugged construction

- Longer service life

- Robust construction

- Low Operation cost

Specification

- Automatic Grade: Semi-Automatic

- Welding Type: Other Welding Equipment

Precision and Versatility for Electrode Manufacturing

This production line is engineered to accommodate a broad range of electrode types and diameters, offering remarkable flexibility for manufacturers. With an adjustable speed up to 120 m/min and a production capacity of up to 36 tons per day, it is suitable for large-scale or custom production. The built-in dust collection and cooling systems enhance operational safety and reliability, while the robust, anti-corrosive steel construction ensures longevity in demanding industrial environments.

Smart Automation and User-Friendly Operation

Equipped with an intuitive touch-screen HMI and PLC-based control system, the line streamlines operations and enables precise process adjustments. Automatic binder feeding, variable speed control, and advanced overload protection make this system energy efficient and safe. Whether operated in semi-automatic or fully automatic mode, the design prioritizes user comfort and ease of maintenance, supporting both new and experienced operators.

FAQ's of Welding Electrodes Production Line:

Q: How does the automatic binder feeding system improve the electrode production process?

A: The automatic binder feeding system ensures consistent and precise addition of binder materials, minimizing human error and maintaining uniform electrode quality. This enhances the efficiency of the production process and helps in achieving higher productivity rates.Q: What types of electrode coatings are compatible with this production line?

A: The welding electrodes production line is compatible with rutile, basic, and cellulosic coating materials, allowing manufacturers to produce a diverse range of electrode types for various welding applications.Q: When is it necessary to use the built-in dust extraction unit?

A: The dust extraction unit should be used continuously during electrode coating and processing steps where dust generation is significant. This system maintains a cleaner work environment, protects equipment, and meets occupational safety standards.Q: Where can this electrode production line be installed and what space is required?

A: The production line is suitable for installation in industrial workshops and manufacturing plants. It requires a minimum area of 70 square meters, allowing sufficient space for safe operation and maintenance activities.Q: What benefits do the touch-screen HMI and PLC-based control system provide to operators?

A: The touch-screen HMI and PLC-based controls make the system user-friendly, enabling easy monitoring, troubleshooting, and adjustment of process parameters. This reduces operator strain, ensures efficient operation, and contributes to consistent output quality.Q: How does the cooling system ensure safe and efficient operation?

A: The combination of water and air cooling systems safeguards critical components from overheating, maintains optimal operating temperatures, and prolongs equipment life, ensuring the production line can run at high capacity with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Electrode Plant Category

Welding Electrode Dry Mixer Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Mild Steel with Powder Coating

Noise Level : Low

Drive Type : Electric Motor Driven

Control System : Panel controlled

Welding Electrode Plant Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Mild Steel & MS/SS Parts

Noise Level : Low < 75 dB(A)

Drive Type : Electric Driven

Control System : PLC Based Control Panel

Welding Electrode Plants

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Mild steel/Alloy steel/SS contact parts

Noise Level : Less than 75 dB

Drive Type : Electric

Control System : PLC based control panel

Welding Electrode Manufacturing Plants

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Mild Steel & Stainless Steel

Noise Level : 80 dB

Drive Type : Electric

Control System : PLC Based Automatic Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free